Traditional irrigation systems play an irreplaceable role in agricultural production. However, they face challenges such as increasing water shortages and low land use efficiency. As an important part of modern agricultural technology, micro-sprinkler irrigation systems are widely used in the production of various crops. Its high efficiency and water saving characteristics have become an effective way to solve the problems faced by traditional irrigation systems.

Micro sprinkler nozzle types and working principles

There are various types of sprinklers in

micro sprinkler irrigation systems, and each type has its own unique working principle and applicable scenarios. Understanding the different types of sprinklers and how they work is essential for efficient irrigation in agricultural production.

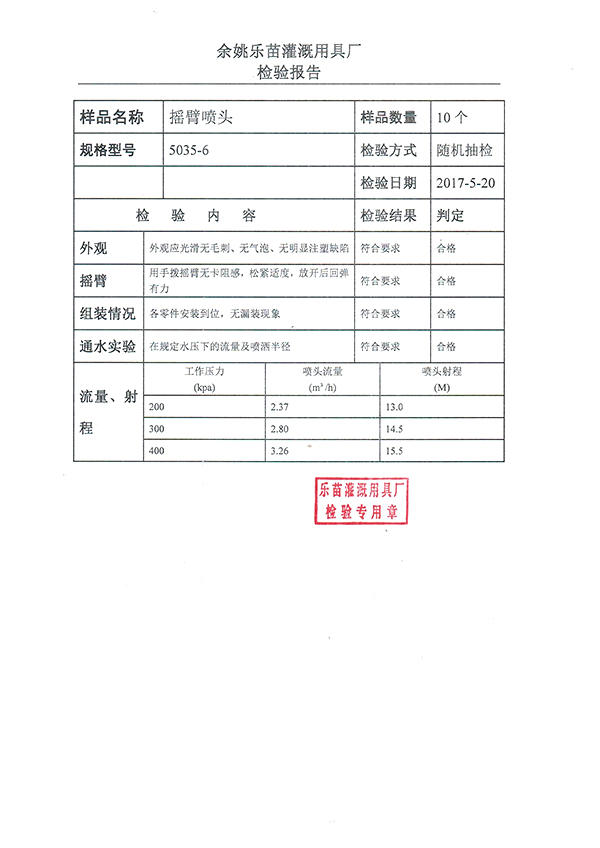

Rotating nozzle

Rotary sprinklers are the most common type of micro-sprinkler irrigation system. Its working principle is to use the power of water flow to rotate the sprinkler head and spray water evenly onto the surrounding land. This type of nozzle usually consists of a nozzle and a rotating mechanism.

Working principle: When the water flow enters the nozzle, the power of the water flow will cause the rotating mechanism to rotate, thereby driving the nozzle to rotate. The nozzle head is designed with nozzle holes, and water is sprayed through the nozzle holes to form a water curtain, which covers a wide range and is suitable for irrigation of field crops.

Applicable scenarios: Rotary sprinklers are suitable for farmland with large planting areas and wide crop spacing. It has a wide spray range and can efficiently cover a large area of land, making it an ideal choice for field crop irrigation.

Fixed sprinkler head

The fixed sprinkler head is fixed at a specific position, and the spray range and intensity of water can be controlled by adjusting the nozzle size and water pressure of the sprinkler head. This kind of sprinkler head is suitable for irrigation of small areas and can achieve precise irrigation of crops.

Working principle: The working principle of the fixed sprinkler head is relatively simple. By adjusting the size and water pressure of the nozzle on the sprinkler head, the spray range and intensity of the water are controlled. The water is transported to the sprinkler head through the pipe, and after being adjusted, it is sprayed out and evenly covered on the crops.

Applicable scenarios: Fixed sprinklers are suitable for irrigation of small areas, such as flower beds, orchards, etc. Its irrigation range can be adjusted according to actual needs, enabling precise irrigation of specific areas.

Spray nozzle

The spray nozzle atomizes water into small droplets and sprays it evenly around the plants, making it suitable for irrigation in facility agriculture and orchards. The spray nozzle can adjust the degree of atomization and spray range of water spray to meet the irrigation needs of different crops.

Working principle: The spray nozzle atomizes water into small droplets through high-speed rotation or high-pressure spray, and then sprays the water droplets evenly around the plants. The process of water atomization reduces the surface tension of the water, allowing the water to penetrate into the soil more easily.

Applicable scenarios: Spray nozzles are suitable for irrigation in facility agriculture and orchards, especially in environments where air humidity needs to be maintained. It can effectively reduce air humidity, prevent the occurrence of pests and diseases, and improve crop yield and quality.

System components of micro sprinkler irrigation system

The micro sprinkler irrigation system is a modern agricultural irrigation technology. Its system consists of water sources, water pipelines, sprinklers, control systems and other components. Each component plays an important role and together constitute an efficient, water-saving system. irrigation system.

Water source

The water source is the basis of the

micro-sprinkler irrigation system, which provides the water resources needed for irrigation. The water source can be groundwater, surface water or artificial reservoir, etc. Choose the appropriate water source according to the actual situation. When selecting a water source, factors such as water quality, water quantity, and water pressure need to be considered to ensure the normal operation of the irrigation system.

Water pipeline

Aqueducts are systems of pipes that carry water from a source to an irrigated area. Water pipelines are usually made of PVC pipes, PE pipes and other materials, which are corrosion-resistant and pressure-resistant. The design of water transmission pipelines needs to consider factors such as pipeline layout, pipe diameter, and construction technology to ensure that water can be smoothly transported to the irrigation area.

Nozzle

Sprinklers are one of the most critical components of a micro-sprinkler irrigation system and are responsible for spreading water evenly over the crops. According to different water spraying methods, nozzles can be divided into various types such as rotating nozzles, fixed nozzles, and spray nozzles. Different types of sprinkler heads have different water spray ranges and water spray intensities, and the appropriate sprinkler head type can be selected according to the needs of the crop.

Control System

The control system is the brain of the micro-sprinkler irrigation system. It is responsible for controlling parameters such as the opening and closing of the sprinkler heads, the amount of water sprayed, and the range of water sprayed. Modern control systems usually use automated control technology to achieve remote monitoring and intelligent adjustment of the irrigation system, improving irrigation efficiency and accuracy.

Filters and Valves

Filters and valves are auxiliary equipment in micro-sprinkler irrigation systems. They play a role in filtering water quality and regulating water flow. The filter can filter impurities and suspended solids in the water, prevent the nozzle from clogging, and ensure the quality and uniformity of water spray. Valves are used to adjust the size and direction of water flow to ensure the stable operation of the irrigation system.

Auxiliary equipment

In addition to the above main components, the

micro sprinkler irrigation system may also include some auxiliary equipment, such as water pumps, pools, sprinkler vehicles, etc. Water pumps are used to increase the water pressure of water sources to ensure that water can be smoothly transported to the irrigation area; pools are used to store water resources to cope with dry seasons or unstable water sources; sprinkler irrigation vehicles can realize mobile irrigation and flexibly respond to different terrains and crop needs.